When copy paper is printed, the double-sheet control or gap of the offset press should be increased accordingly; the distance between the paper pressing tongue of the side gauge and the front gauge and the cardboard, and the distance between the safety bar and the cardboard should be increased. .

When cutting and positioning printed packaging paper, a packaging paper positioning slitting machine must be used. The positioning slitting machine must be a printed copy paper or printed packaging paper used to standardize patterns. Because of its specific pattern and size, ordinary slitting machines Is it so accurate, and the efficiency is very busy or the material waste is huge. The positioning slitting machine can choose any specification of printing range and distance, so that the printing of bright packaging paper sheet by sheet can be evenly cut to achieve a beautiful effect.

The production of general copy paper printing is divided into two basic processes: pulp and paper making. Pulp is the use of mechanical methods, chemical methods or a combination of the two methods to dissociate plant fiber raw materials into natural pulp or bleached pulp. Papermaking is the process of combining pulp fibers suspended in water into paper sheets that meet various requirements through various processes.

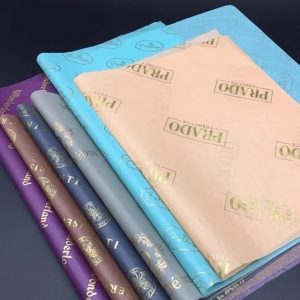

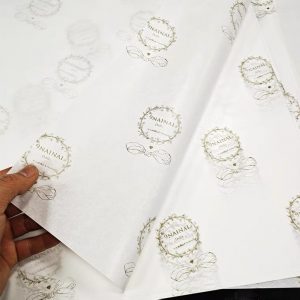

Copy paper printing: Copy paper has a good printing effect. It can print single color, two-color, four-color, corporate logo, trademark, and can be dyed into various colors such as red, blue, gold, and silver.